Weld engineering is always available to MTI customers, and our highly skilled welding team is here to help you review your job plans and processes. Our team is trained in both manual and orbital welding and meets all ASME Sec IX criteria. MTI maintains ASME Certificates of Authorization, including: 'PP,' 'U,' 'S,' and 'R' stamps, to ensure our dedication to public safety and quality work.

From carbon steel and stainless to Inconel and chrome (P11, P22, P91), we maintain strict adherence to our safety and quality standards to assure your project is completed on time and in a safe, professional manner.

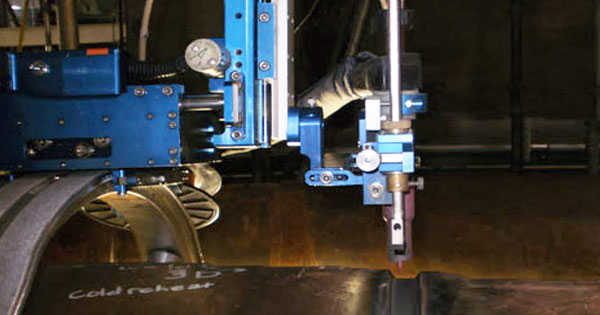

MTI Power Services is an expert in automatic orbital welding. When it comes to jobs with many critical welds, nothing can stack up to narrow groove's efficiencies. You receive the same quality and speed no matter how difficult the access or how unfriendly the environment is. Visit https://www.solarorbitalsystems.com/ to learn more.

Our welding team works one-on-one with customers to review manual welding job plans and implement the welding technique that will work best for their needs. Our staff has the experience necessary to meet all ASME sec. IX criteria and are trained at the MTI Mock-up, Training, and Certification Facility in Marseilles, IL.

MTI has years of experience in large OD pipe welding. Our welders are tested and certified on every appropriate welding technique and are here to help you see your project through to completion. Our welders have experience with large OD pipes and vessels and meet all ASME Sec IX criteria.

MTI has considerable experience in the welding of exotic materials, including stainless and duplex (ferritic, austenitic, precipitation hardened), high-nickel alloys, chrome (P11, P22, and P91), Inconel, and Hastelloy.

Our team of welding techs and engineers is here to help you review your job plans and ensure the job is completed on time and in a safe and professional manner. MTI Staff will be there to:

MTI offers the most qualified machining and welding personnel in the business and claims a 100% customer satisfaction record in field service projects. We have tested and certified over 200 welders. Our reputation in the business is one that few can match. We feature the best-trained welders, project managers, supervisors, and technicians in the business.