MTI manufactured field machining equipment maintains the highest level of quality and construction. Rest assured, your project will finish on schedule and on budget. We provide equipment and experienced technicians for uncommon on-site machining requirements such as facing elliptical manway gasket sealing surfaces.

We provide a wide variety of equipment rentals to businesses across various sectors, including power plants, oil and gas facilities, paper mills, and beyond.

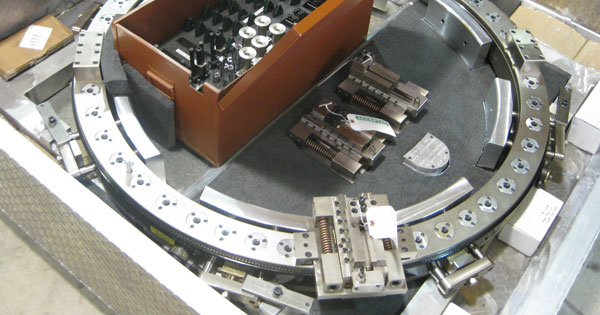

MTI Split Frames are the world’s most versatile and comprehensive line of clamshell style portable pipe cutting and beveling machine tools on the market today. Designed to cut, bevel, single point, counterbore and face flanges on pipe and tubing ranging from .5 to 84 inches O.D. (DN15-2100) on most wall thicknesses and materials, MTI has a split frame to fit most size pipe, tube or vessels.

What does it mean to own the finest split frame in the world? The lowest cost to operate of any machine. You own the most versatile machine available. You own the most durable machine in the world. You get the finest warranty in the business.

What you won’t get: Bills for broken and worn parts. Excuses about ability to make difficult cuts. Additional costs for bridge slides. Excuses about holding tolerances.

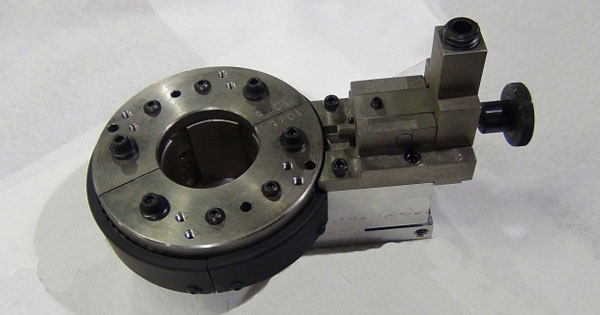

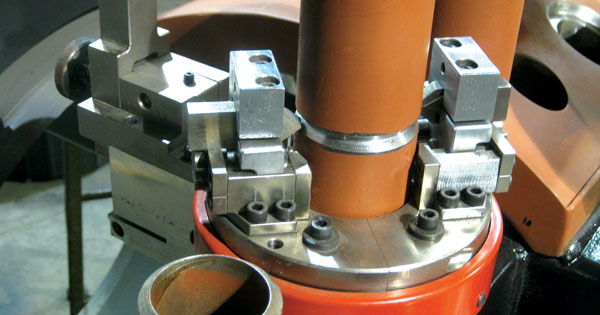

SOLID RING Split Frames are available for sale or rental. These machines are particularly effective for customers involved in high production environments or specialty applications where the highest machining tolerances possible are required.

What does it mean to own the finest split frame in the world? The lowest cost to operate of any machine. You own the most versatile machine available. You own the most durable machine in the world. You get the finest warranty in the business.

What you won’t get: Bills for broken and worn parts. Excuses about ability to make difficult cuts. Additional costs for bridge slides. Excuses about holding tolerances.

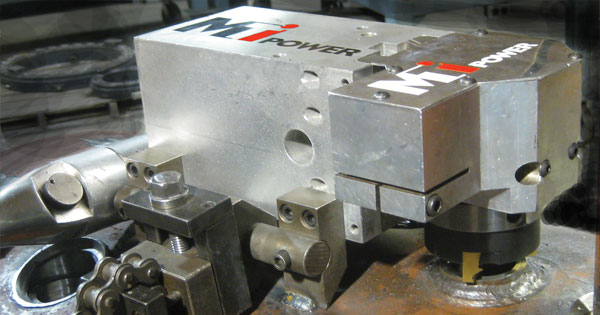

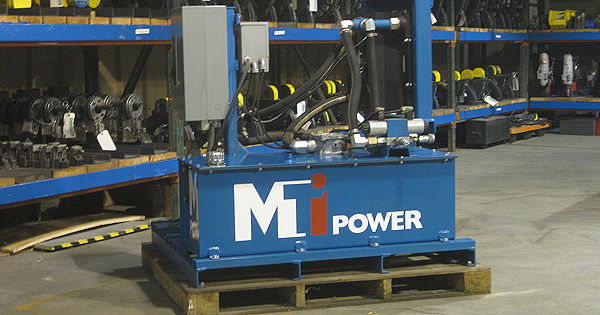

MTI POWER manufactures the most reliable and adaptable ID mount pipe facing, beveling, and grooving equipment in the world. The 414 and 624 are no exception – the rigidity of these machines allows them to do jobs the others can’t.

Coming soon.

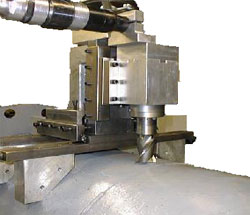

Portable MTI machines cut, drill, tap and bore virtually any wall thickness and pipe diameter (no matter what material) quickly and easily with no complications. The finest field machinists and welders in the world are accomplished in our machine shop, our testing facility and on-site. These are the people who will work on your job. The best person for the job using the finest gear available – that’s MTI.

MTI machines cut, drill, tap and bore virtually any wall thickness and pipe diameter (no matter what material) quickly and easily with no complications.

MTI has mag base and saddle machines to work in virtually any envelope, wall thickness and diameter (no matter the material) always quicker, always easier – no complications.

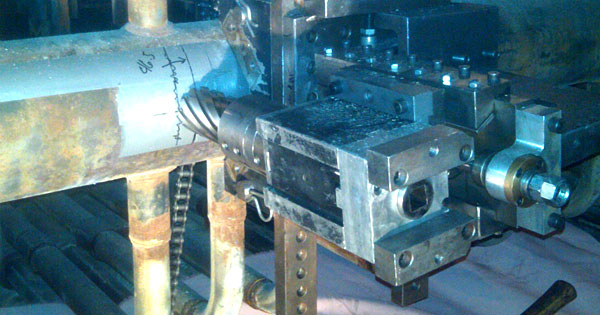

MTI Power has exceptional tools for gamma holes and plugs. Go through these pictures to see some of the projects we’ve done. Frozen studs, heavy wall pipe or super duplex materials are no match for our legendary cutting tools.

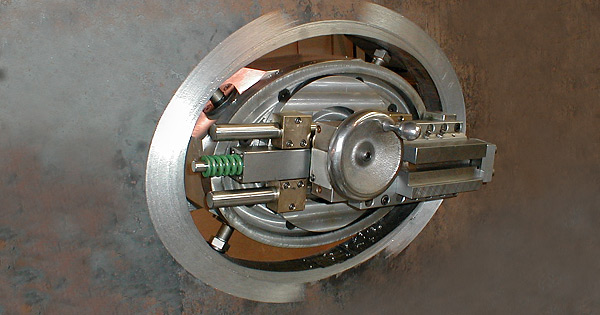

MTI Power has invented boring equipment that no other company has. There are designs that mount to MTI Split Frames and free-standing machines – all of them are MTI “unstoppable”.

Portable machines manufactured by MTI are so tough and well-built that they function as a portable machine shop. Versatility = Value

Every year, MTI POWER preps hundreds of boiler tubes for welding. Often, orbital tube welding is specified. 20* J-bevels and counterbores with close tolerances (.005″) are required.

MTI has created a line of specialty machines that will quickly mount to the boiler tube and remove a bad weld, leaving an excellent machined surface ready for welding.

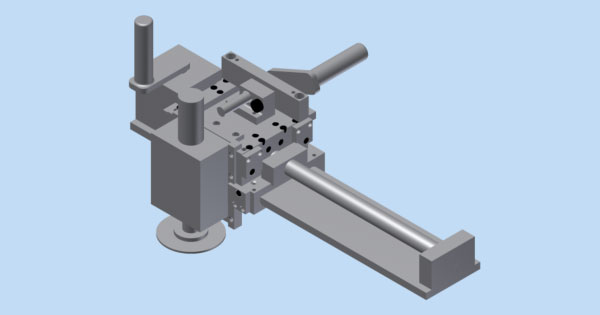

MTI designed a machine that simplifies the process of machining stub tubes. This machine increases production and has clearance advantages. The design worked so well that the customers at the site started calling it the “Johnny Neutron” in reference to the cartoon JIMMY NEUTRON Boy Genius.

We developed a method to speed the process of Header Stub Tube Machining. We have designed machines that cut offset seats and perpendicular seats – these machines cut the socket seat, radius and weld bevel.

Coming Soon.

Coming Soon.